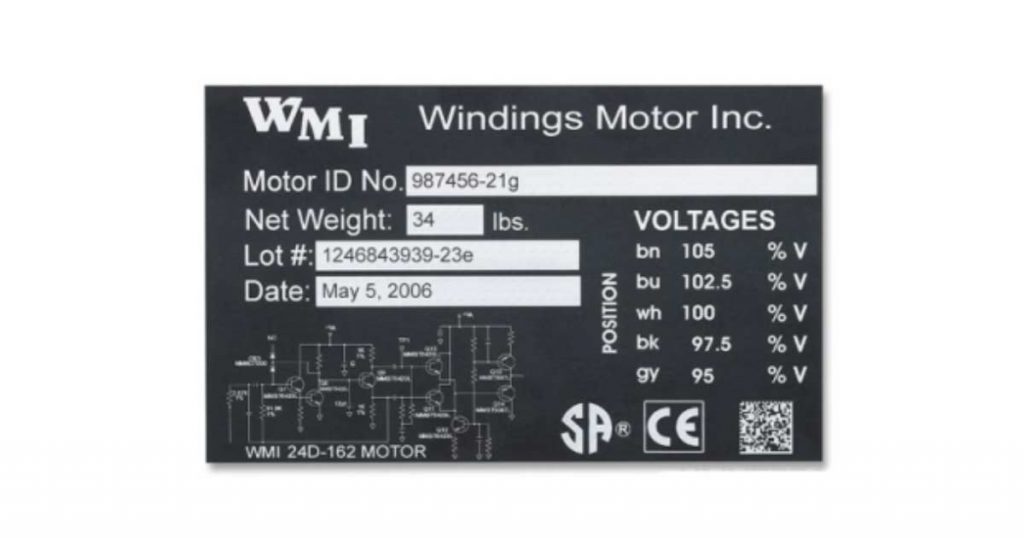

Nameplates - Panels - ID Tags

High Quality Nameplates made to last

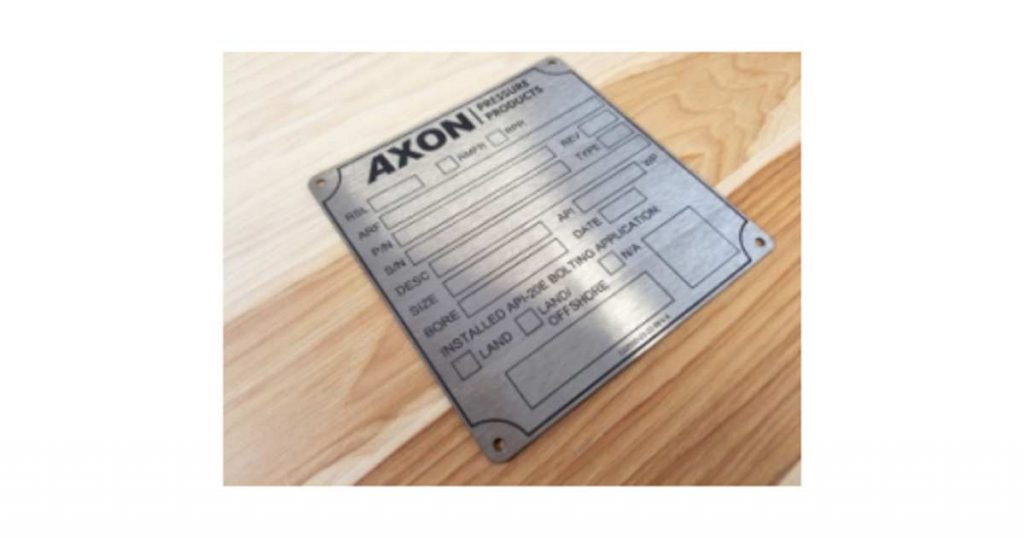

Stainless Steel Nameplates

Strength and durability. Stainess steel is ideal for challenging environments where heat, moisture and corrosion are factors.

In the most challenging conditions, especially heavy industrial environments, where heat, moisture, and corrosion are present, stainless steel nameplates are the superior

choice to overcome these obstacles. One of the most common used metals,

stainless steel produces great strength and durability without increasing weight to

the nameplate. Our stainless steel nameplates are everlasting and feature excellent resistance against corrosion and many chemical solvents.

- Exceptional physical properties, including strength and durability.

- Minimal maintenance and upkeep necessary.

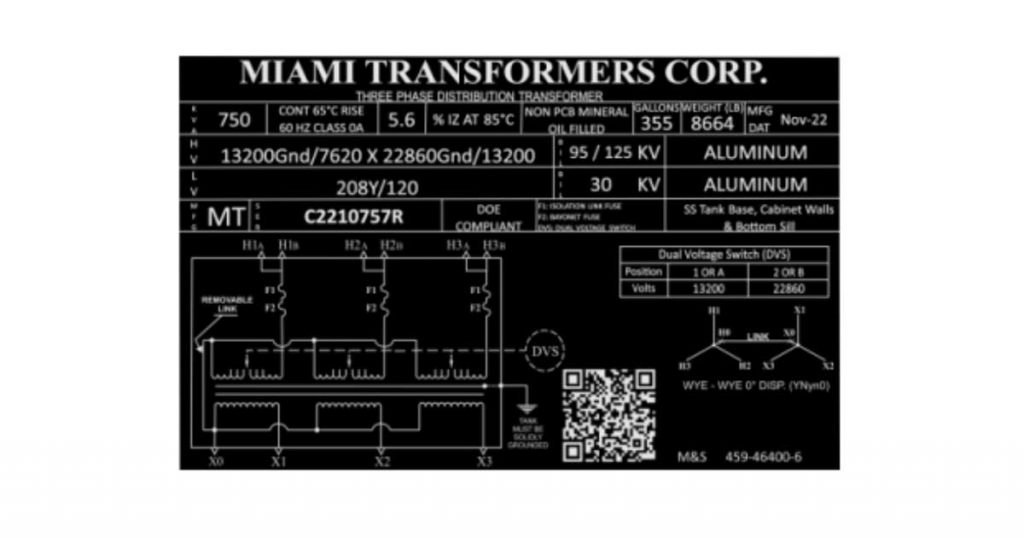

Aluminum Nameplates

Lightweight yet durable material that is versatile for a variety of applications. Including aerospace, manufacturing, transportation and military.

Aluminum has become a popular material choice for nameplates in many industries

due to it’s inherent properties. Suitable for harsh environments and rigorous conditions. Our nameplates are lightweight, resistant to corrosion, high temperatures and chemicals, and tend to be more economically feasible compared to other metal nameplates. Versatile in nature, aluminum nameplates are produced to your custom specifications.

- Strong, lightweight and cost effective.

- Laser engraving ensures precise printing.

- Useful in applications including aerospace, manufacturing, transportation

and military.

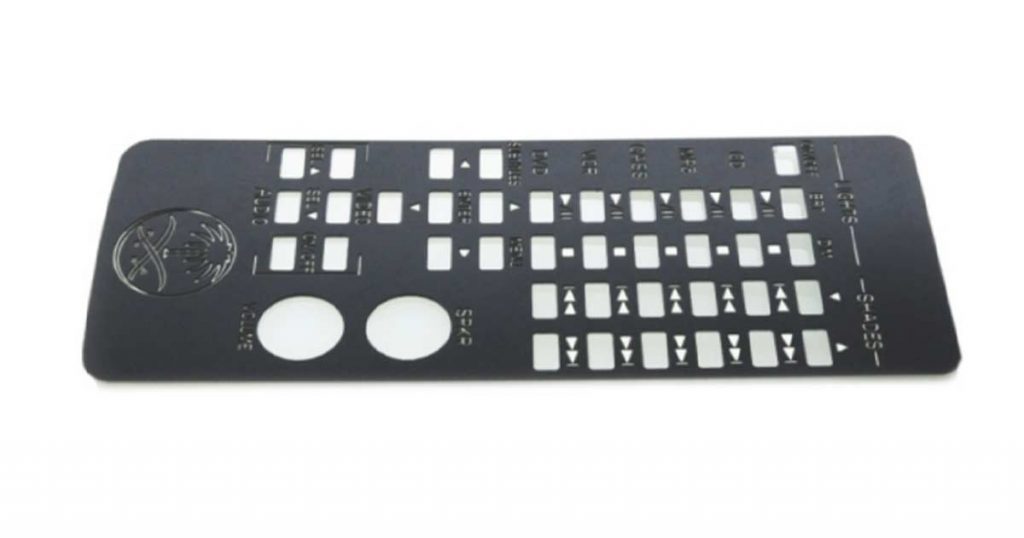

Engraved Plastics

Featuring superior materials. Weatherproof and UV stable for outdoorand indoor use.

Our acrylic plastic materials are engineered for indoor and outdoor use. They

are ideal for a wide range of applications, including industrial and electrical marking, signage, and security.

- Versatile acrylic material built to endure the most rigorous conditions.

- Durable, precise and highly effective.

- Available in a wide variety of contrasting colors, thicknesses, Including .020” thick with industrial adhesive backing to mold to curved surfaces.